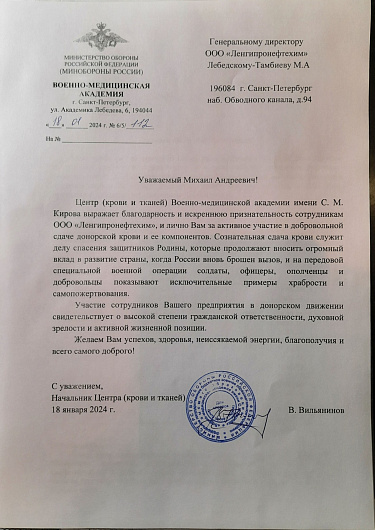

Contacts

Telefax:

+7 (812) 316-36-01

+7 (812) 316-83-45

+7 (812) 740-60-48

E-mail:

Mail address:

94 Naberezhnaya Obvodnogo Kanala, POB 206, Saint-Petersburg, Russia, 196084